Fuel tanks are parts for storing gasoline and light oil as automotive fuel. Fuel is necessary for automobiles, but is also a dangerous material due to its high flammability characteristics. Accordingly, fuel tanks are regarded as important safety-related parts, and Yachiyo develops fuel tanks by putting the top priority on customer’s safety, such as fuel containment not only during normal use, but also in case of automobile collisions.

Conventionally, fuel tanks mainly consist of a steel plate. But, in recent years, the resinification of fuel tanks is promoted in order to improve the adaptability to automotive design and respond to weight reduction. Yachiyo has established the system to separately manufacture products having specifications utilizing advantages of steel and resins in accordance with destinations and environmental regulations, according to customer’s request.

The environment surrounding automotive fuel tanks can be significantly different from each other depending on customer’s requirements such as, types of cars and destinations with different environmental regulations, needs for new automobiles and the diversification of design. Yachiyo has its own R&D division to have the unified system from basic research to product development, manufacturing technologies and mass production.

Furthermore, Yachiyo challenges the realization of high quality and high productivity on the basis of its accumulated technologies and know-how, and, in recent years, Yachiyo proceeds with the development of not only fuel tanks themselves, but also the entire “fuel tank system” including peripheral parts from a fill opening to a tank body, in addition to self-supplying and self-manufacturing of sub-parts mounted on products.

As automotive parts, Yachiyo promotes further weight reduction of fuel tanks. By employing a new material (high-rigidity material), while the rigidity, pressure tightness, shock resistance and the like of fuel tank bodies are maintained, the thickness of tanks is reduced to the limit. As a result, 15% weight reduction of fuel tanks is realized compared to the conventional fuel tanks.

As automotive parts, Yachiyo promotes further weight reduction of fuel tanks. By employing a new material (high-rigidity material), while the rigidity, pressure tightness, shock resistance and the like of fuel tank bodies are maintained, the thickness of tanks is reduced to the limit. As a result, 15% weight reduction of fuel tanks is realized compared to the conventional fuel tanks.

Yachiyo proceeds with consideration on new part constituting methods as well as thickness reduction aiming to provide further weight reduction.

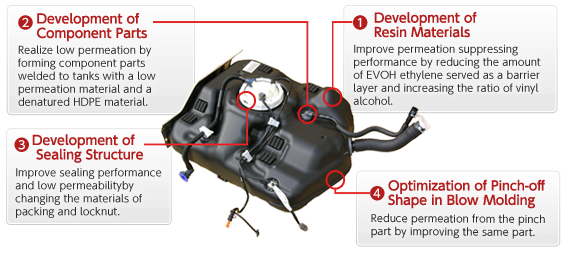

Yachiyo’s plastic fuel tanks comply with the most strict automotive exhaust emission regulation, PZEV*. Yachiyo, having plastic fuel tanks as one of its main products, independently proceeded with R&D activities on the material ratio and tank materials to quickly commercialize fuel tanks complying with the PZEV regulation.

Yachiyo continuously improves product strengths in both of the top class safety and environmental consideration.

PZEV stands for Partial-Credit Zero Emission Vehicle. PZEV is a strict exhaust emission regulation enacted by the California Air Resource Board.

In manufacturing lines of plastic fuel tanks, high productivity is established under the following systems.

| Automated Transportation System |

|

|---|---|

| Two Lines System of Secondary Working | High flexible lines that synchronize with manufacturing models and timing of customers. |

Parts Feeding System “Karakuri” |

System for efficiently replacing boxes of parts with empty boxes at the time of mounting parts after secondary working. |

| Inspection Equipment Utilizing Helium Gas | Extremely highly accurate inspection system detecting the pressure variation of the helium gas is used in order to prevent gasoline leakage as the basic function of the fuel tank. |

Automated Transportation System

Secondary Working Line

Inspection Equipment Utilizing Helium Gas

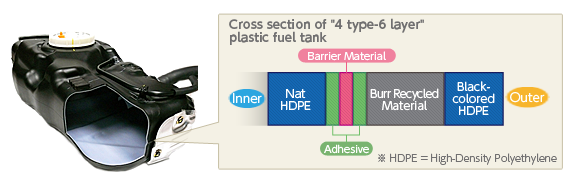

Plastic Fuel Tanks manufactured by Yachiyo have a “4 types-6 layers” structure in which 4 different materials are configured as 6 layers to be blow-molded. Yachiyo realized the commercialization of plastic fuel tanks for mass production vehicles first in Japan, and brought the tanks to market for the Honda’s first hybrid vehicle “Insight”.

The 4 different materials include a high function resin (Eval) as well as the main material (high density polyethylene). Therefore, permeation of a volatile component of gasoline (HC: hydrocarbon) is suppressed remarkably. Furthermore, the mounting method of tank constituent parts is improved. So, Yachiyo’s plastic fuel tanks comply with the strictest exhaust emission regulations in the world, PZEV.

Since plastic fuel tanks are lightweight, free from corrosion and able to comply with various environmental regulations, they are becoming the mainstream in recent years.

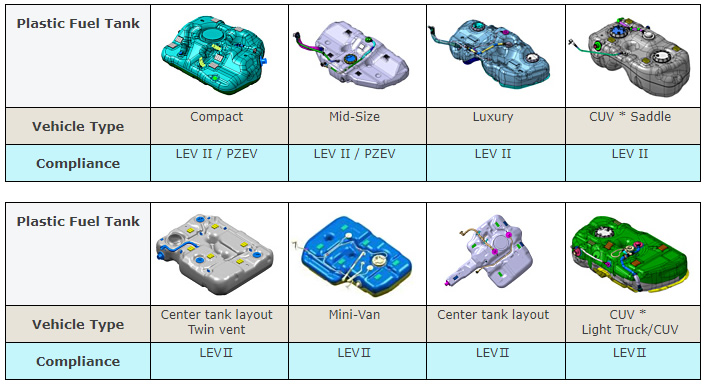

*CUV:Cross Over Utility Vehicle

Steel fuel tanks are formed by welding upper and lower iron plates press-molded into a vessel-like shape. Yachiyo’s fuel tanks started from this type of steel tanks and Yachiyo has accumulated unique know-how as a fuel tank manufacturer. Although the production volume is decreasing due to the increase in demand for plastic fuel tanks in recent years, Yachiyo provides steel fuel tanks that meet customer’s request according to automotive characteristics.

Steel fuel tanks are formed by welding upper and lower iron plates press-molded into a vessel-like shape. Yachiyo’s fuel tanks started from this type of steel tanks and Yachiyo has accumulated unique know-how as a fuel tank manufacturer. Although the production volume is decreasing due to the increase in demand for plastic fuel tanks in recent years, Yachiyo provides steel fuel tanks that meet customer’s request according to automotive characteristics.